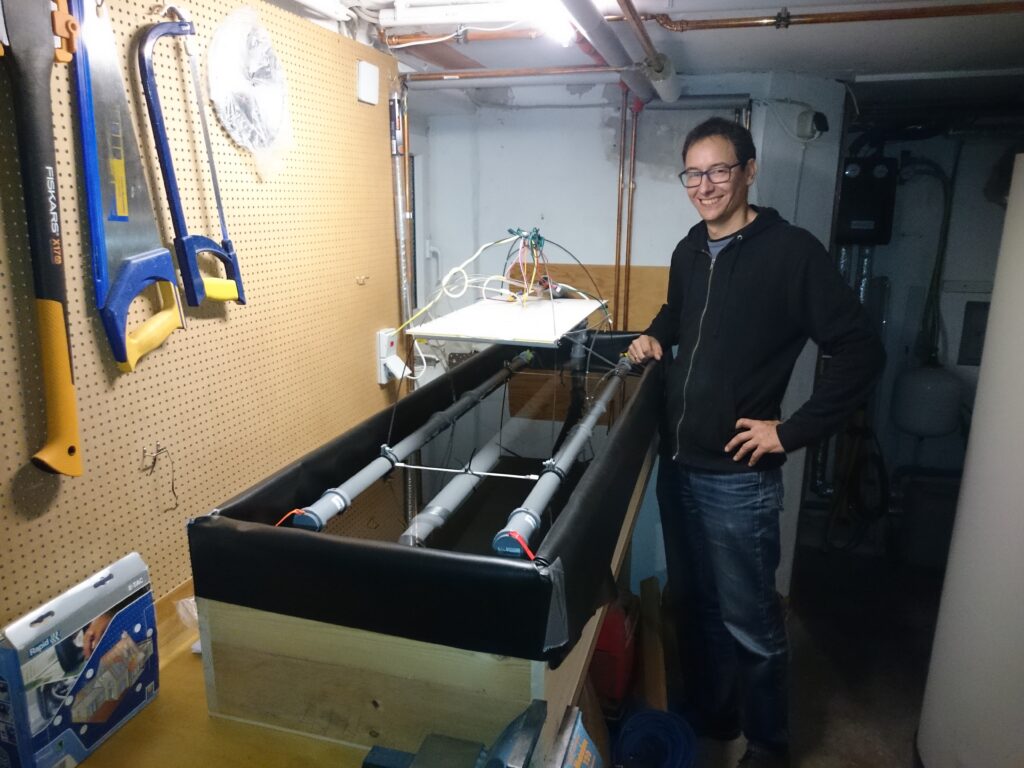

The proof of the pudding is in the eating. And therefore it is a common practice in the design process of a new vessel to create a prototype scale model. To find out, if we manage to keep the three tubular based, submarine-like hull and the deck platform balanced while sailing through wind and waves, we have to test it in action. I shared my plans with my friend Dirk, an experienced mechanic and electronic technician, and luckily he decided to get on board. Discussing the scale for the functioning proof of concept we decided that roughly 1:100 would be best for us to handle. And that is why the euphonic working title for the project would be OHANDA ONE 1:100 – aka o1.01 (o-one-zero-one).

Let’s go shopping!

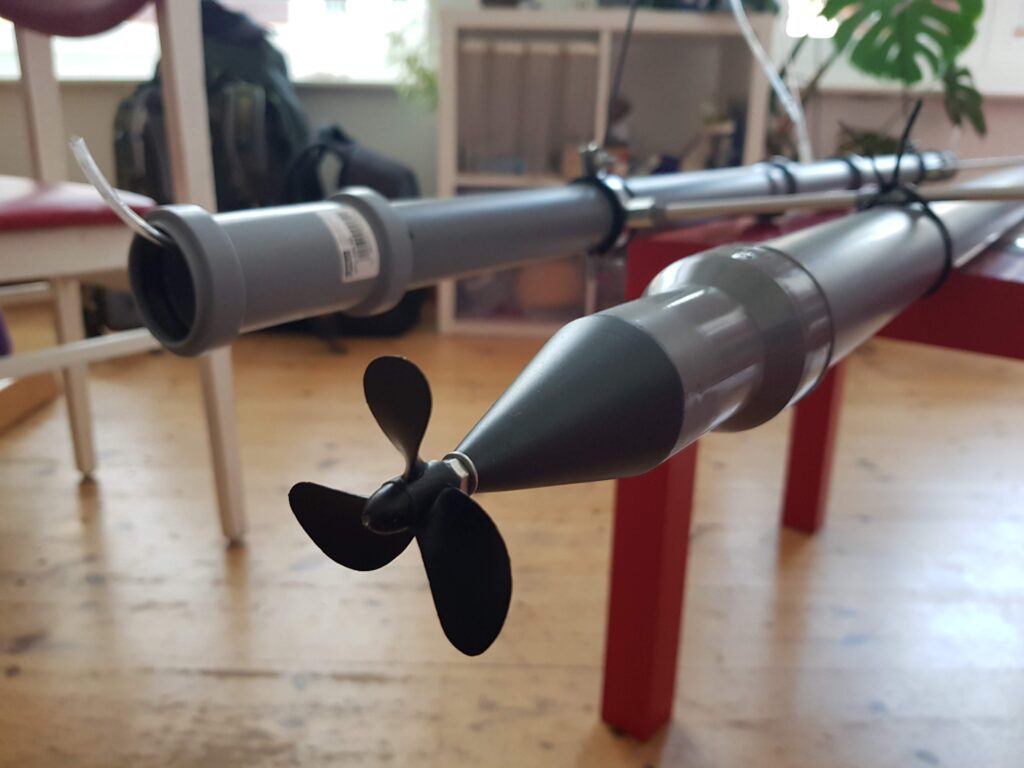

The last time I visited an RC model shop was about 40 years ago. So I had a real flashback when looking at all the tiny gadgets and tech toys inside the store. The hardest part was the consulting talk with the salesperson trying to explain what kind of ship we were planning to build and that everything needed to fit into a ø50mm plastic tube. But he really did a good job and so I left the store with a second hand radio control and receiver, a brushless electric motor with controller, servos, a set of rechargeable batteries, steven pipe, ship propeller, cables and lots of other bits and pieces required for the basic ship operation.

In addition to that we ordered small magnetic valves, pneumatic pumps and tubes required to fill the two side tubes with air.

Putting it all together

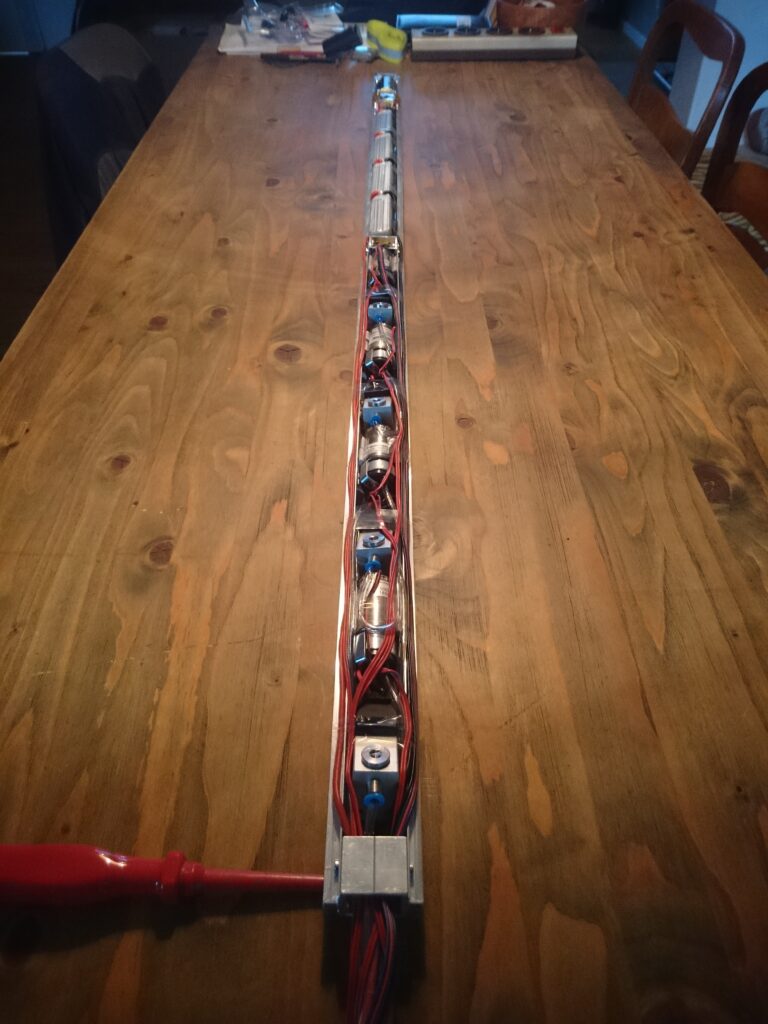

To fit everything into the center plastic tube we use a frame made of aluminum rails. Each side tube will be split in 2 sections with separate balance tanks to independently control the front (bow) and the rear (stern) for the left side (portside) and the right side (starboard). Over all we use 4 batteries, 4 pumps and 4 valves. All other electronics will be stored above the water surface on the deck.

![]()