To keep the center of mass low while hovering above the water surface, the deck construction should be as lightweight as possible. At the same time it is the fastening of the masts and servos with fixing points for the vertical and edge-gated fin pylons. Therefore the construction needs a certain level of mechanical stability. The material of choice for these requirements clearly is carbon fiber. Luckily one finds a great variety of profiles in well-assorted crafts shops these days.

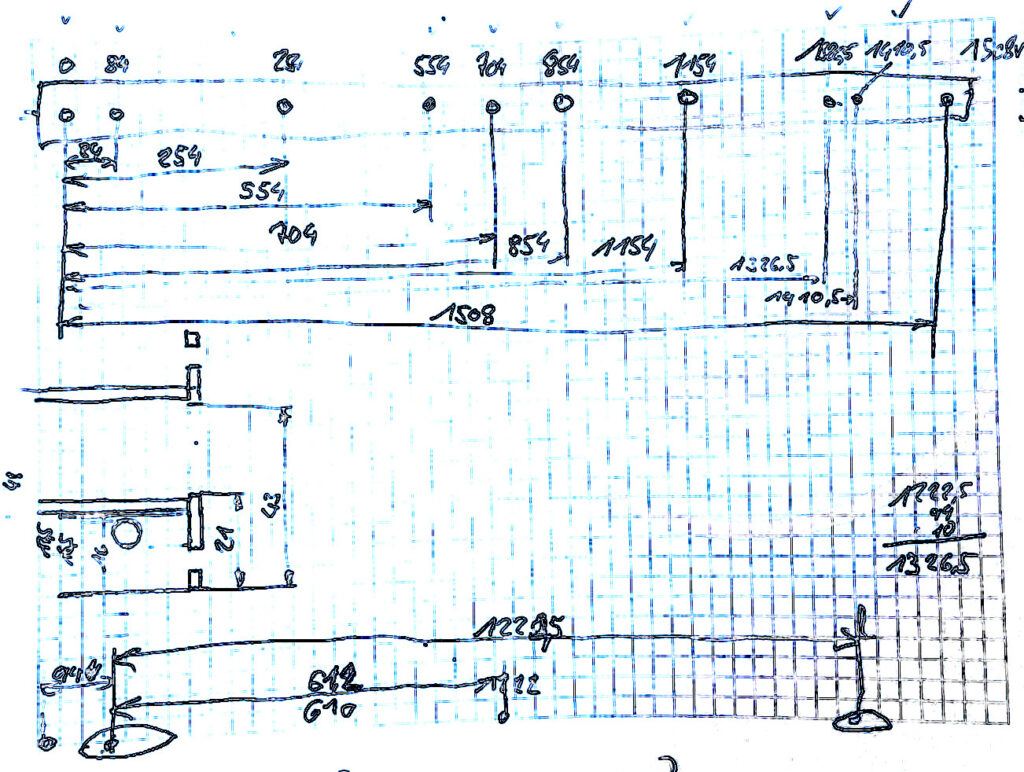

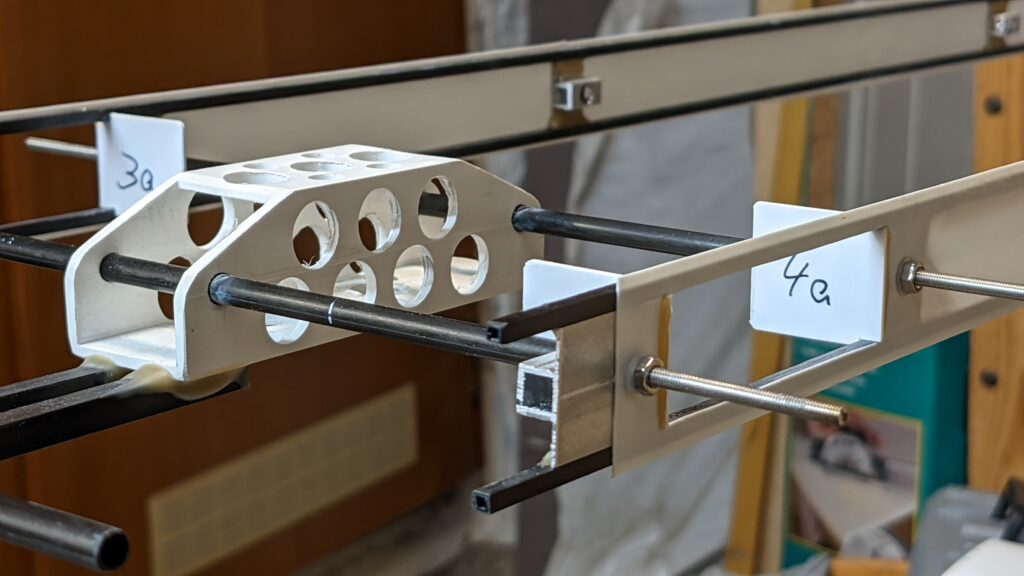

For better maintainability we want the deck platform to be removable from the hull. To start with we plan the future connection points for the masts and the edge-gated pylons between nose and tail which we drill in aluminum profile auxiliary rails.

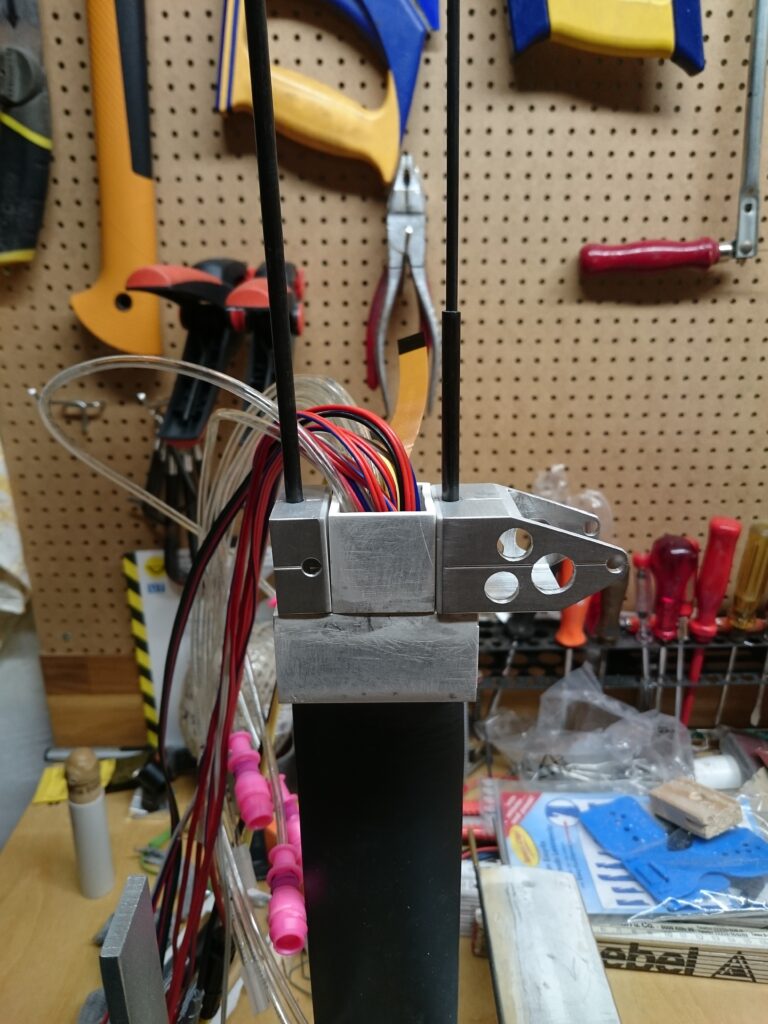

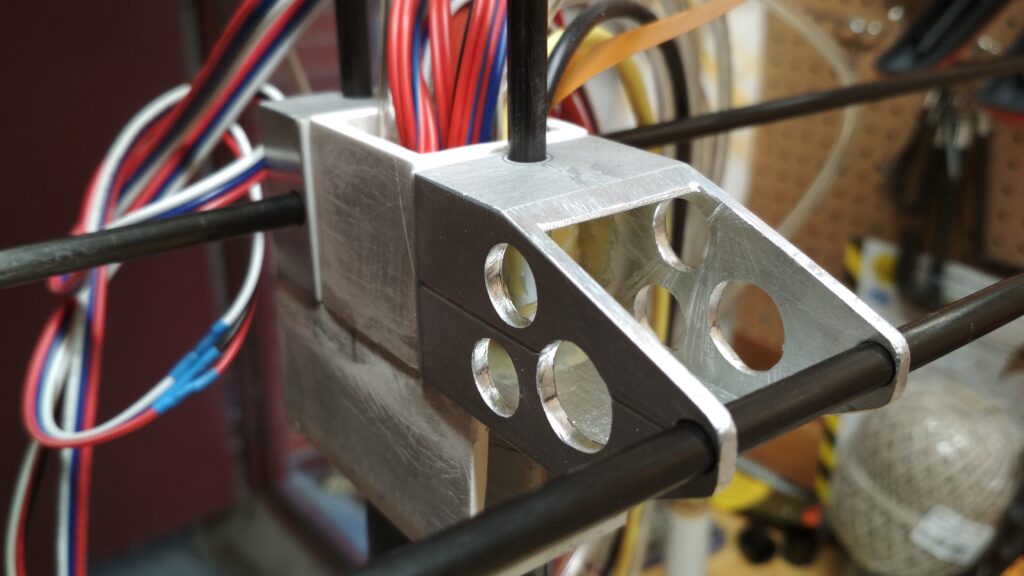

Next we build bearing connections on the nose and tail pylon.

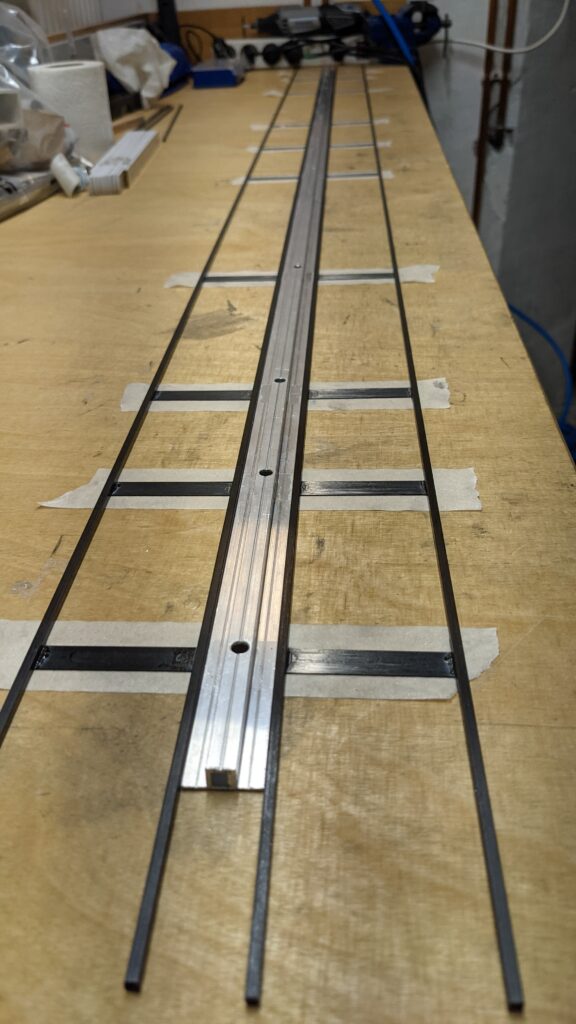

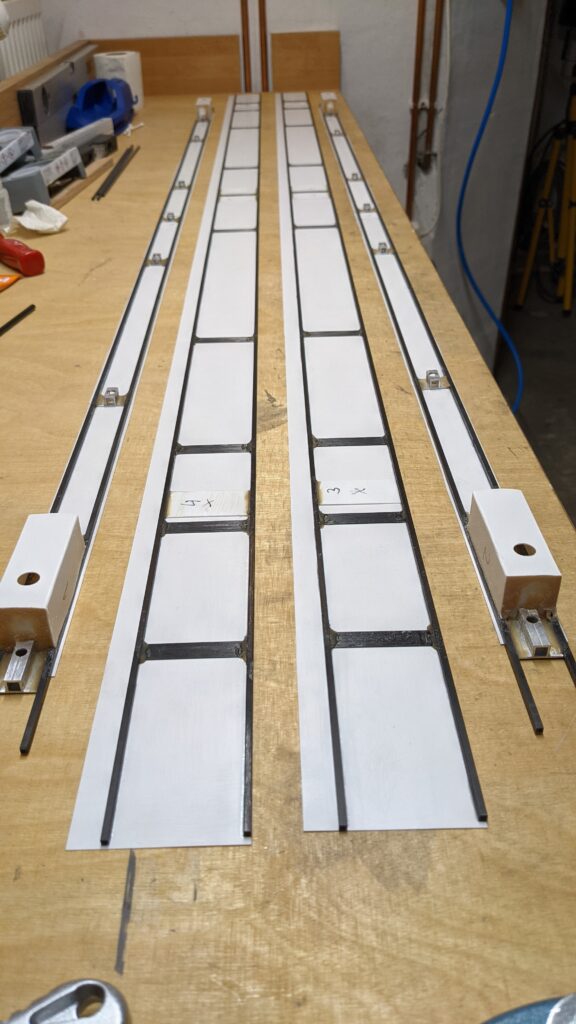

Next we build the carbon fiber framework with the help of the auxiliary rails.

We plank the framework with 0,3 mm polystyrene boards.

![]()