Clearly Einstein would not agree that energy equals mass unless we multiply the latter with c². But in case of the shiplet we appreciate that we do not have to consider higher spheres of physics when it comes to shifting the center of gravity a little further down the hull and add a ballasted keel to improve its tipping stability. At the same time adding extra weight feels a bit wrong, because each extra gram will require more energy to be moved. To somehow balance this dilemma, instead of adding pure mass, we decide to add a pile of extra batteries to the keel, so that finally each gram we add is not just ballast, but it adds extra energy. Another positive result is to achieve a second and independent electric circuit to the existing on-board electronics.

For the battery beam we use 16 pieces of 3,7 V lithium-ion rechargeable cells with 3000 mAh each which we organize in one long row of 4×4 clusters to produce 14,8 V and 12 Ah. Each battery weighs about 50 gr. To solder it all together we use flexible flat stranded copper wire bands.

To one end of the row we add a heavy metal coated 5 pole XLR connector (plus, minus and three control lines to balance the charging current) and pack everything in a shrinkable tubing. Then we test it.

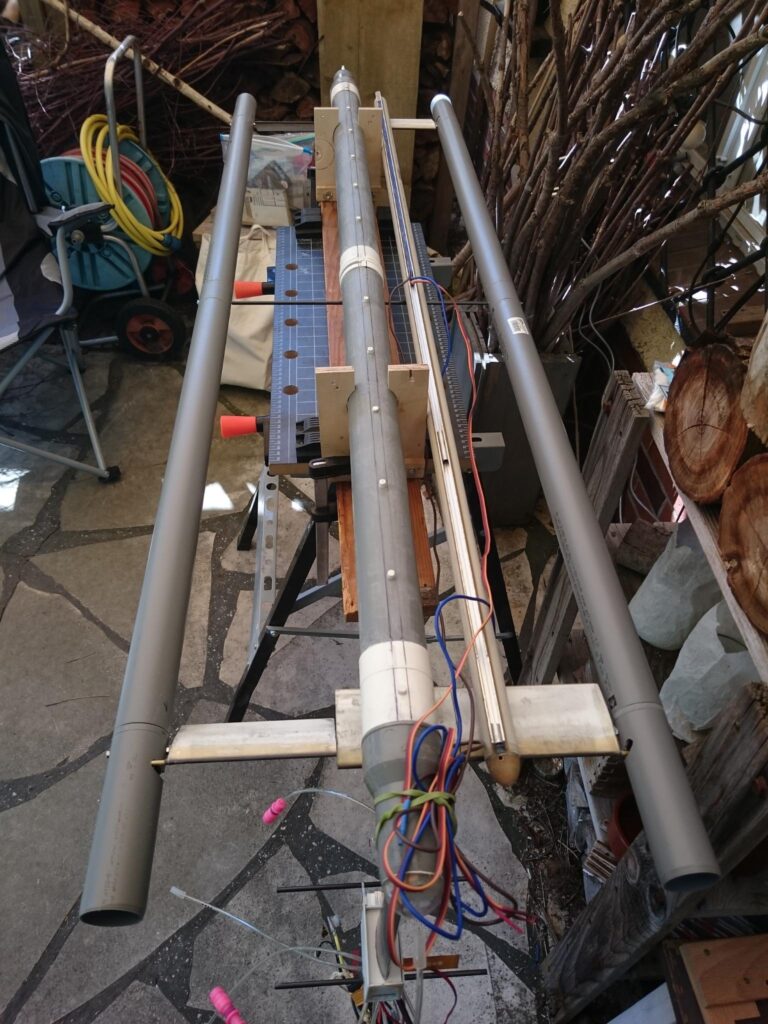

We fit the battery pack into a ø25 mm plastic tube and stopple one end with a wine cork. We screw a big hex-head screw with a bunch of shims into the cork to balance the weight of the XLR connector at the other end. Only the outer end of XLR connector is glued into the tube, so that the connection can still be unplugged to extract the battery pack from the plastic tube, if needed. Finally we paste head and tail with a lot of glue which we then smoothen to some sort of hydrodynamic shape.

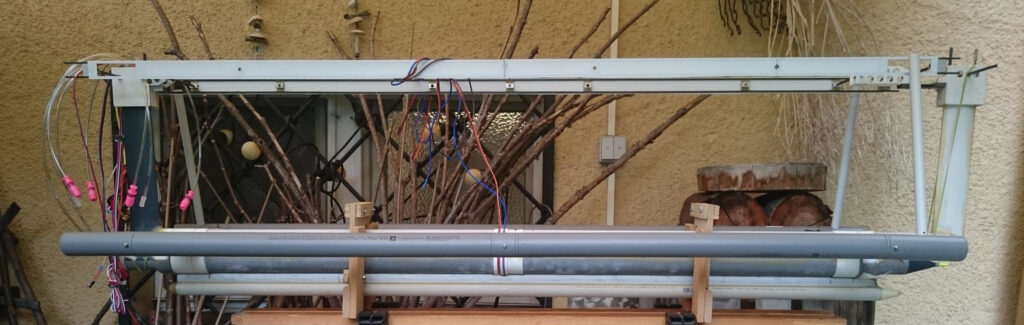

To attach the new battery beam under the center tube we use a 20 x 6 mm aluminum H-section profile rail. The rail adds some extra weight to the bottom of the hull and the extra distance and additional profile improves the stabilizing effect of the roughly 1100 gr weighing battery pack underneath. We also use the rail as cable channel to lay the cables into the middle of the hull where they are run around the center pipe and will be conducted towards the deck through a vertical middle fin pylon.

To improve the stability of the bonded joint between the aluminum rail and the HT drain pipe and also to add guidance to the elongate bonding seam we first add a row of plastic fittings to the bottom of the hull.

Finally we glue it all together.

![]()