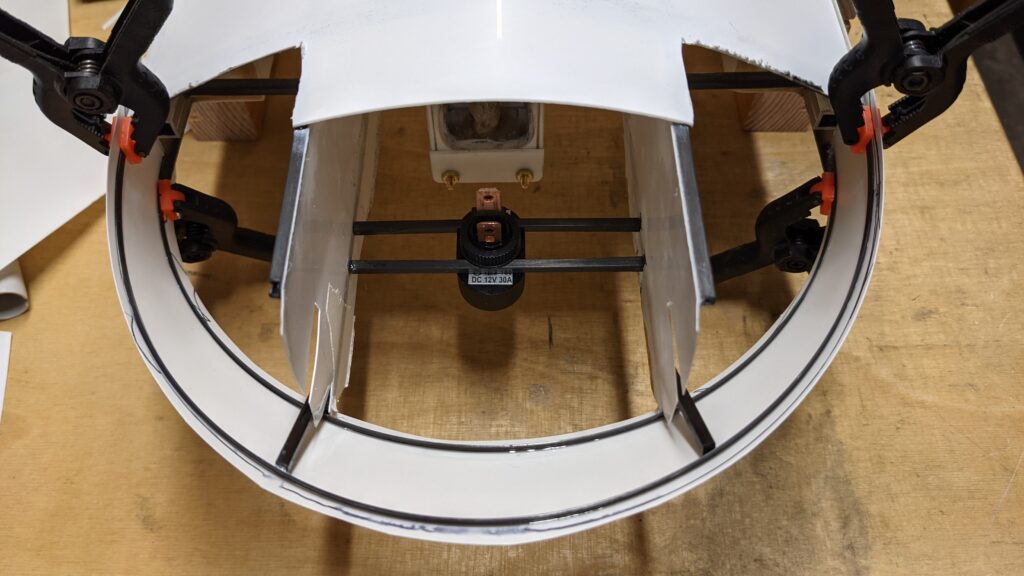

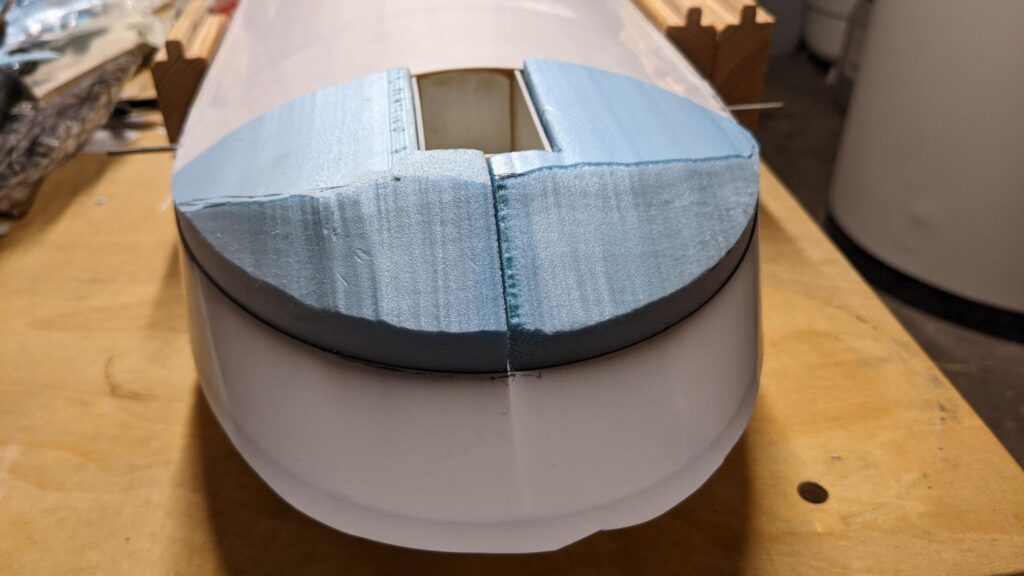

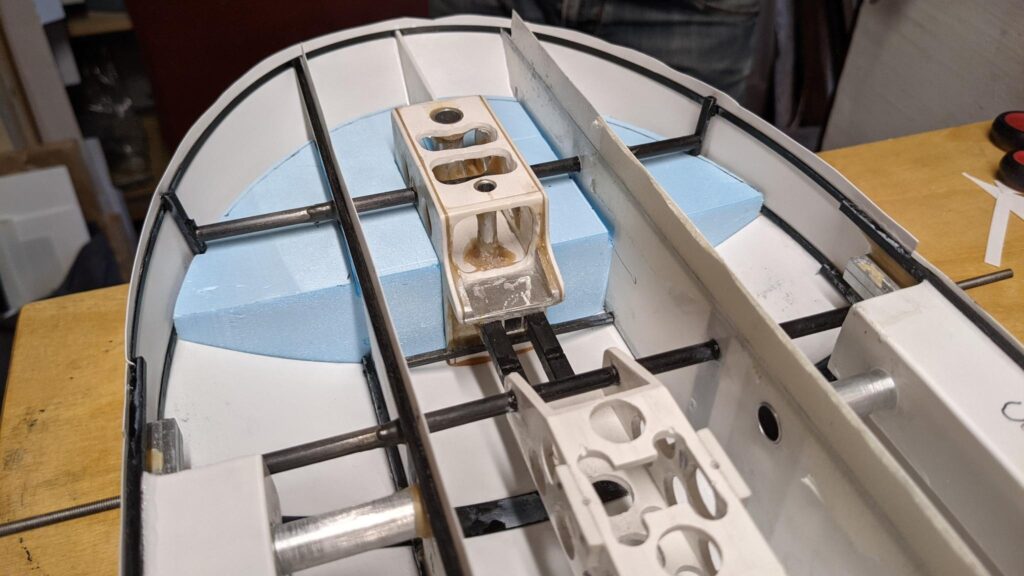

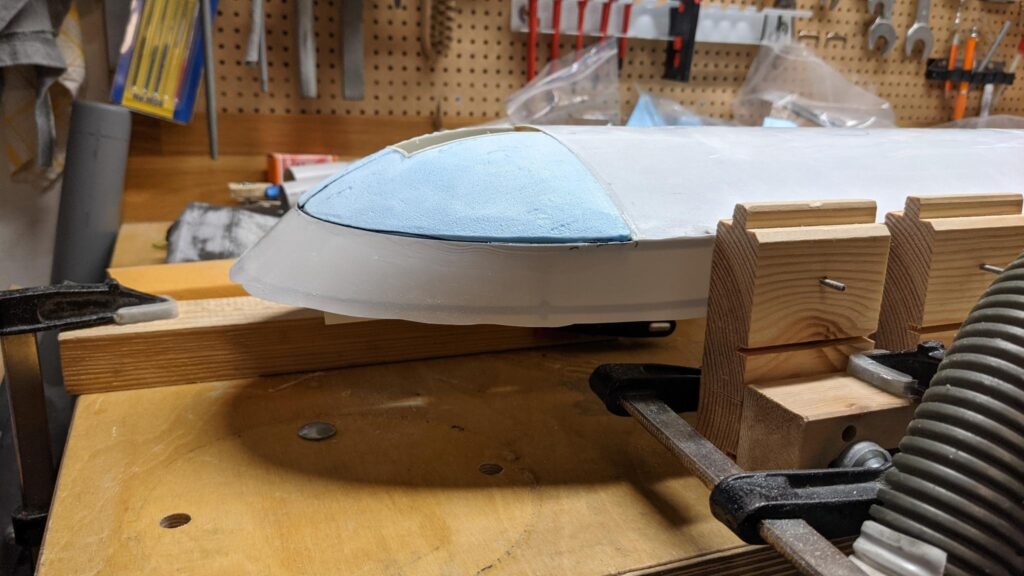

Even though the shiplet’s deck is supposed to hover above the waterline and to never even touch it, we thought it might be a good idea to design it like a ship itself, which will swim (… just in case …). After finalizing the carbon fiber framework we plank the rounded floor section with 0,5 mm Akrylnitril-Butadien-Styrol (ABS) boards. At nose and tail we use rigid foam to smoothly shape the curved transitions.

![]()